KPI COUNTERS – THE SCOREBOARD

Why Change?

Pain-Point Matrix

View Our AI Fix

View On‑Screen Friction

View Our AI Fix →

View On‑Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

See the data fly

Workflow Spotlight

AI Solutions

RFQ & ECO Intelligence

Key points

- Real-time S&OP alignment for procurement workflows.

- Up to 15 % inventory reduction through predictive RFQs.

- Integrates with SAP IBP / Kinaxis for bid and change automation.

Predictive Maintenance

Key points

- Detects anomalies across assets using real-time telemetry.

- Reduces unplanned downtime by up to 40 %.

- Integrates seamlessly with SCADA and ERP systems.

Computer Vision QC

Key points

- Automates visual inspection with defect-classification AI.

- Achieves > 96 % accuracy in surface-defect detection.

- Deployable on edge devices for real-time response.

RL Scheduling

Key points

- Reinforcement-learning agent tunes energy consumption dynamically.

- Yields up to 18 % efficiency gain in HVAC and process loads.

- Compatible with IoT sensors and grid controllers.

Voice Assistant

Key points

- Custom LLM-based assistant for operations and support.

- Context-aware queries across ERP, CRM and MES systems.

- Cuts manual search time by > 55 %.

Demand Planner

Key points

- AI-driven forecast engine with multivariate models.

- Reduces inventory holding cost by up to 20 %.

- Integrates with SAP IBP / Kinaxis for real-time alignment.

Under the hood

Technical Architecture

- NVIDIA Jetson Xavier / PLC gateway

- RTSP < 15ms

- TLS 1.3

- PyTorch Lightning -> ONNX, Tritron inference

- AutoML cost-model for RFQ

- Prophet + probabilistic transformer for demand

- FastAPI micro‑service cluster (RFQ & ECO extractor, Demand Planner API)

- Confluent kafka

- Snowflake Lakehouse

- Delta clone

- MQTT for IIOT

- Kubeflow

- Argo CD GitOps

- ISO 27001 vault

- React + D3 dashboards

- Grafana OT metrics

- Hololens AR overlay

Implementation Blueprint

Phase 1: Discover & Data Audit

- Process walk‑through

- Sensor-map

- Sample RFQ/ECO extraction

- ROI hypothesis.

Phase 2: Rapid Pilot

- One line + one commercial flow instrumented

- Baseline KPIs captured

Phase 3: Shadow validation

- 24 x 7 inference in parallel

- Operator & sales‑team feedback loop

Phase 4: Production Launch

- MES/ERP integration live

- Staff training

- SLA activated

Phase 5: Continuous Optimisation

- KPI review

- Model retrain

- Feature backlog burn-down

ROI Calculator

Revenue Uplift:

Scrap Savings:

Payback:

Trust & Compliance Badges

The Fast Lane

Give us 30minutes. We’ll map a milestone‑based AI path that pays for itself.

Why Choose Us

Future-Ready AI,

Backed by Proven Trust

We design interfaces that feel modern, smooth, and engineered for factory precision—visualizing process parameters, machine health, and quality KPIs in real time.

Trusted by leading electronics, FMCG, chemical, and industrial manufacturers—validated through ISO, GMP, and industry-specific compliance frameworks.

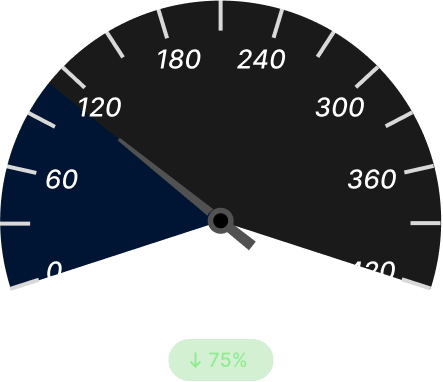

Without AI:

We help stabilize your process before small variations become expensive failures.

Start with a short assessment call, no commitment needed, to uncover where predictive insights can enhance uptime and reduce waste.