KPI COUNTERS – THE SCOREBOARD

Why Change?

Pain-Point Matrix

View Our AI Fix

View On‑Screen Friction

View Our AI Fix →

View On‑Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

View Our AI Fix

View On-Screen Friction

See the data fly

Workflow Spotlight

AI Solutions

RFQ Intelligence

Key points

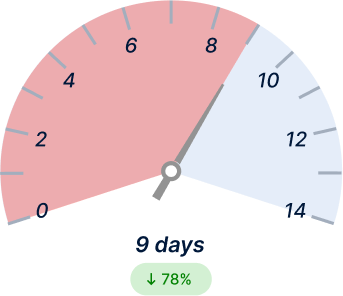

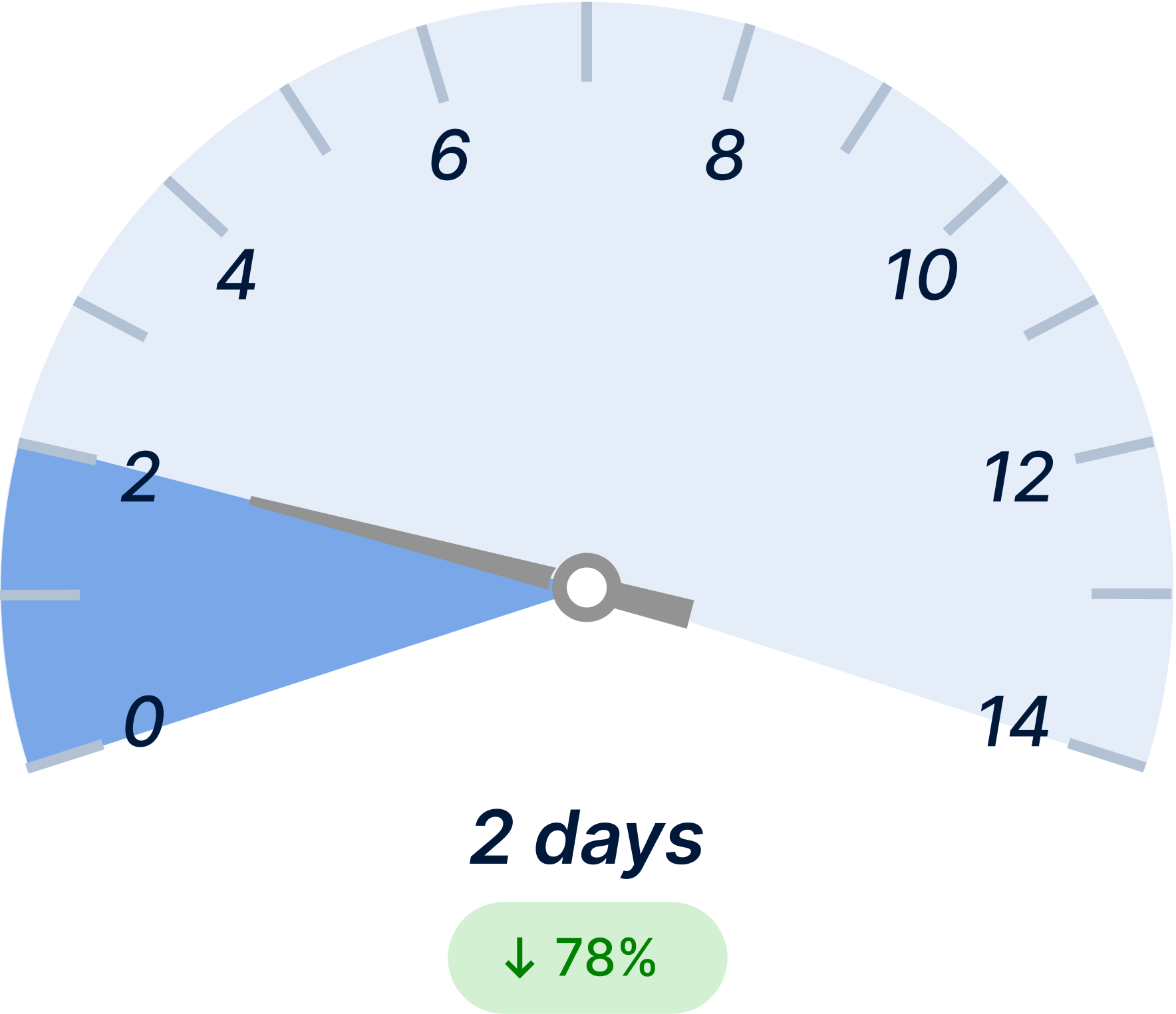

- 78% faster quote cycle.

- +4pp win-rate.

- Compatible with SAP, Oracle, Epicor.

Predictive Maintenance

Key points

- Real-time machine monitoring.

- Prevent unplanned downtime.

- Increases asset lifecycle.

Computer Vision QC

Key points

- Automated defect detection.

- Reduces human inspection errors.

- Faster production QA cycles.

RL Scheduling

Key points

- Optimizes production schedules.

- Uses reinforcement learning.

- Maximizes efficiency & throughput.

Voice Assistant

Key points

- Natural language interaction.

- Hands-free operation.

- Custom commands for factories.

Energy Optimiser

Key points

- Reduce energy consumption.

- AI-driven suggestions.

- Lower operational costs.

Under the hood

Technical Architecture

- NVIDIA Jetson Orin Nano

- RTSP < 15ms

- TLS 1.3

- PyTorch Lightning -> ONNX

- Triton interence

- Auto-ML cost-model for RFQs

- FastAPI RFQ extractor

- LangChain tool-router

- Fine-tuned Llama 3 for spec matching

- Confluent Kafka

- Snowflake lakehouse

- Delta clone

- Kubeflow, Argo CD

- ISO 27001 / SOC 2 vault

- React + D3 dashboards

- Grafana OT metrics

- Hololens AR overlay

Implementation Blueprint

Phase 1: Discover & Data Audit

- Process walk‑through

- Sensor/BOM map

- Sample data extraction

- ROI hypothesis.

Phase 2: Rapid Pilot

- One line + one commercial process instrumented

- Baseline KPIs captured

Phase 3: Shadow validation

- 24 x 7 dual-lane inference in parallel

- Operator feedback loop

Phase 4: Production Launch

- MES & SAP integration live

- Staff training

- Support SLA activated

Phase 5: Continuous Optimisation

- Monthly KPI review

- Model retrain

- Feature backlog burn-down

Estimated Uplift:

+ $280K / Year

Time Saved:

~60 Days / Year

Estimated Uplift:

+ $720K / Year

Time Saved:

~ 180 Days / Year

Estimated Uplift:

+ $1.2M / Year

Time Saved:

~ 300 Days / Year

Estimated Uplift:

+ $1.7M / Year

Time Saved:

~ 420 Days / Year

Estimated Uplift:

+ $2.4M / Year

Time Saved:

~ 600 Days / Year

Trust & Compliance Badges

The Fast Lane

Give us 30minutes. We’ll map a milestone‑based AI path that pays for itself

Why Choose Us

Proven Results,

Trusted by Experts

Our dashboards deliver fast, precise insights from defect heatmaps to production bottleneck overlays designed to give automotive leaders complete clarity across every assembly line.

Backed by top-tier automotive OEMs and Tier-1 suppliers, our AI systems meet global quality, safety, and compliance benchmarks across APQP, PPAP, and IATF standards.

Without AI:

We help you stop the leakage before it becomes a costly recall.

A 60-minute diagnostic session gives you actionable insights into how AI improves cycle times, yield stability, and supply chain reliability.