AI In Smart Energy Management For Plants

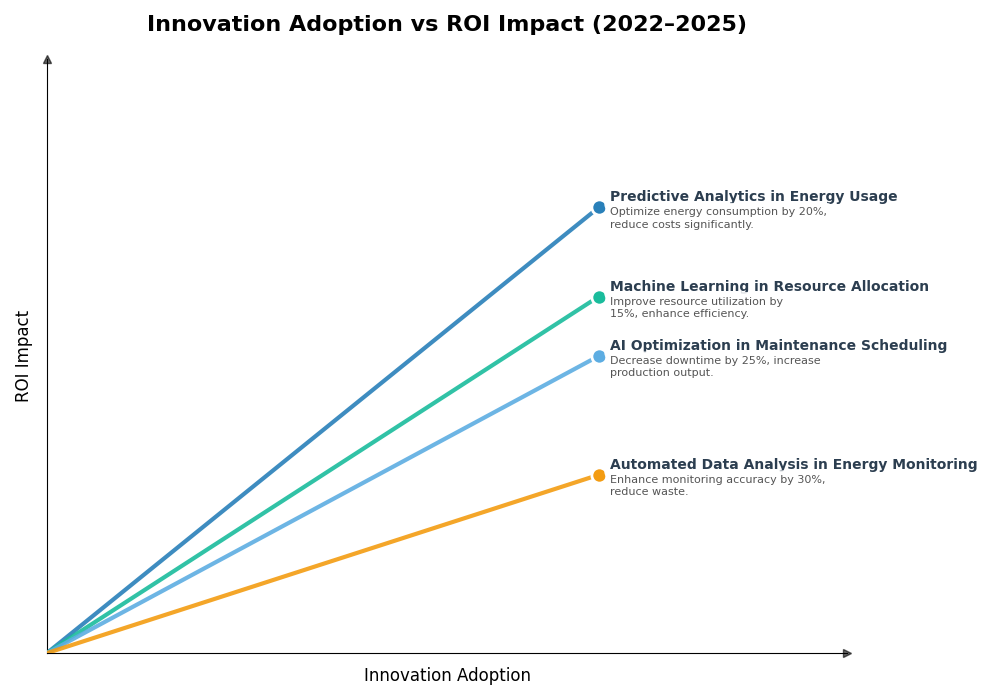

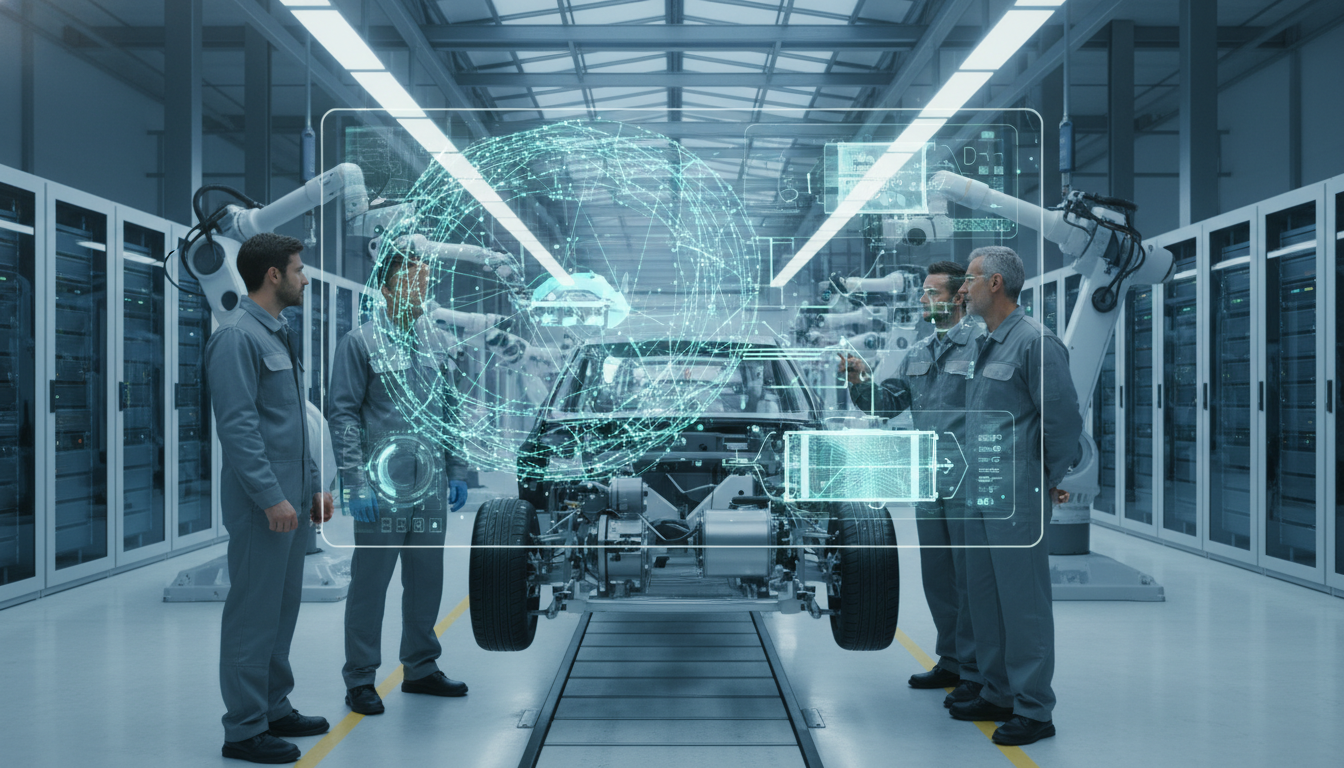

AI in Smart Energy Management for Plants represents a transformative approach within the Automotive sector, integrating advanced artificial intelligence technologies to optimize energy consumption and reduce operational inefficiencies. By leveraging predictive analytics and machine learning algorithms, this concept enables manufacturers to autonomously manage energy resources, aligning with the sector's growing focus on sustainability and operational excellence. This evolution not only addresses immediate energy challenges but also supports broader strategic goals of innovation and competitiveness.

The integration of AI-driven energy management practices is reshaping the Automotive landscape, influencing how organizations innovate and interact with stakeholders. As companies adopt these technologies, they enhance decision-making capabilities and operational efficiency, fostering a culture of continuous improvement. However, the path to effective implementation is not without its challenges, including the complexity of integration and evolving stakeholder expectations. Navigating these factors will be crucial for businesses aiming to harness the full potential of AI in energy management, unlocking significant growth opportunities while addressing inherent barriers to adoption.

Harness AI for Smart Energy Management in Automotive Plants

Automotive companies should strategically invest in AI-driven smart energy management solutions and form partnerships with leading technology firms to enhance operational efficiency. Implementing these AI strategies can significantly reduce energy costs, optimize resource allocation, and ensure a sustainable competitive edge in the market.

How AI is Revolutionizing Smart Energy Management in Automotive Plants

The Disruption Spectrum

Five Domains of AI Disruption in Automotive

Automate Production Flows

Optimize Supply Chains

Enhance Generative Design

Simulate Testing Environments

Boost Sustainability Initiatives

Compliance Case Studies

| Opportunities | Threats |

|---|---|

| Enhance energy efficiency through data-driven AI optimization strategies. | Increased technology dependency may lead to systemic vulnerabilities in operations. |

| Leverage AI for predictive maintenance, reducing downtime and costs. | Workforce displacement due to automation could disrupt employee morale. |

| Differentiate products with innovative AI-driven energy solutions and features. | Compliance challenges may arise from evolving regulatory AI frameworks. |

Seize the opportunity to transform your plant's energy efficiency with AI-driven solutions. Stay ahead of the competition and redefine your operational success now!

Risk Senarios & Mitigation

Failing ISO Compliance Standards

Legal fines apply; ensure regular compliance audits.

Ignoring Data Privacy Protocols

User trust erodes; establish stringent privacy measures.

Inherent Algorithmic Bias

Decision-making flawed; conduct regular bias assessments.

Operational System Failures

Production halts; implement robust backup systems.

Assess how well your AI initiatives align with your business goals

Glossary

Work with Atomic Loops to architect your AI implementation roadmap — from PoC to enterprise scale.

Contact NowFrequently Asked Questions

- AI in Smart Energy Management optimizes energy use through intelligent algorithms and real-time data.

- It reduces waste and improves efficiency in automotive manufacturing processes.

- The technology enables predictive maintenance, enhancing equipment longevity and performance.

- Organizations benefit from lower operational costs and improved sustainability initiatives.

- AI also supports data-driven decision-making for better resource allocation and management.

- Begin by assessing your current energy management systems and identifying gaps.

- Engage with AI solution providers to understand available technologies and services.

- Pilot projects can demonstrate feasibility and refine your approach before full deployment.

- Ensure staff are trained to work with new AI tools and technologies effectively.

- A phased implementation strategy helps integrate AI without disrupting ongoing operations.

- Investing in AI enhances operational efficiency and reduces energy costs significantly.

- It provides a competitive edge by improving sustainability practices and regulatory compliance.

- AI-driven insights lead to better forecasting and resource planning for manufacturing.

- Automotive companies can achieve measurable improvements in production quality and uptime.

- Long-term, AI investments can drive innovation and adaptability in ever-changing markets.

- Resistance to change within the organization can hinder successful AI adoption.

- Data quality and integration issues may complicate the implementation process.

- Lack of skilled personnel can delay project timelines and effectiveness.

- Budget constraints may limit the scope of AI solutions and technologies.

- Establishing clear objectives and metrics is crucial to overcoming these challenges.

- Companies should consider adoption when facing rising energy costs and inefficiencies.

- The right time also aligns with broader digital transformation initiatives within the organization.

- Pilot projects can be initiated during periods of low production activity.

- Regular assessments of energy consumption patterns can signal readiness for AI solutions.

- Engagement with technology partners can provide valuable insights for timing decisions.

- Organizations typically see reduced energy consumption and operational costs after implementation.

- Enhanced equipment performance and lifespan are common benefits of predictive maintenance.

- Improved compliance with environmental regulations can result from optimized energy use.

- Data analytics lead to better decision-making and resource allocation strategies.

- Companies often achieve higher customer satisfaction through improved product quality and reliability.

- AI systems can automate compliance reporting, reducing administrative burdens significantly.

- Real-time monitoring ensures adherence to environmental regulations and standards.

- Data analytics provide insights for proactive adjustments to meet changing requirements.

- Organizations can leverage AI to model scenarios and optimize compliance strategies.

- Integrating AI enhances transparency and accountability in energy management practices.

- AI can optimize HVAC systems to reduce energy consumption in manufacturing plants.

- Predictive maintenance powered by AI minimizes downtime and reduces repair costs.

- Energy usage forecasting helps align production schedules with energy supply variations.

- AI can analyze energy patterns to inform sustainable sourcing and production practices.

- Smart grid technologies integrated with AI enhance overall energy management efficiency.