AI In Simulation Of Manufacturing Lines

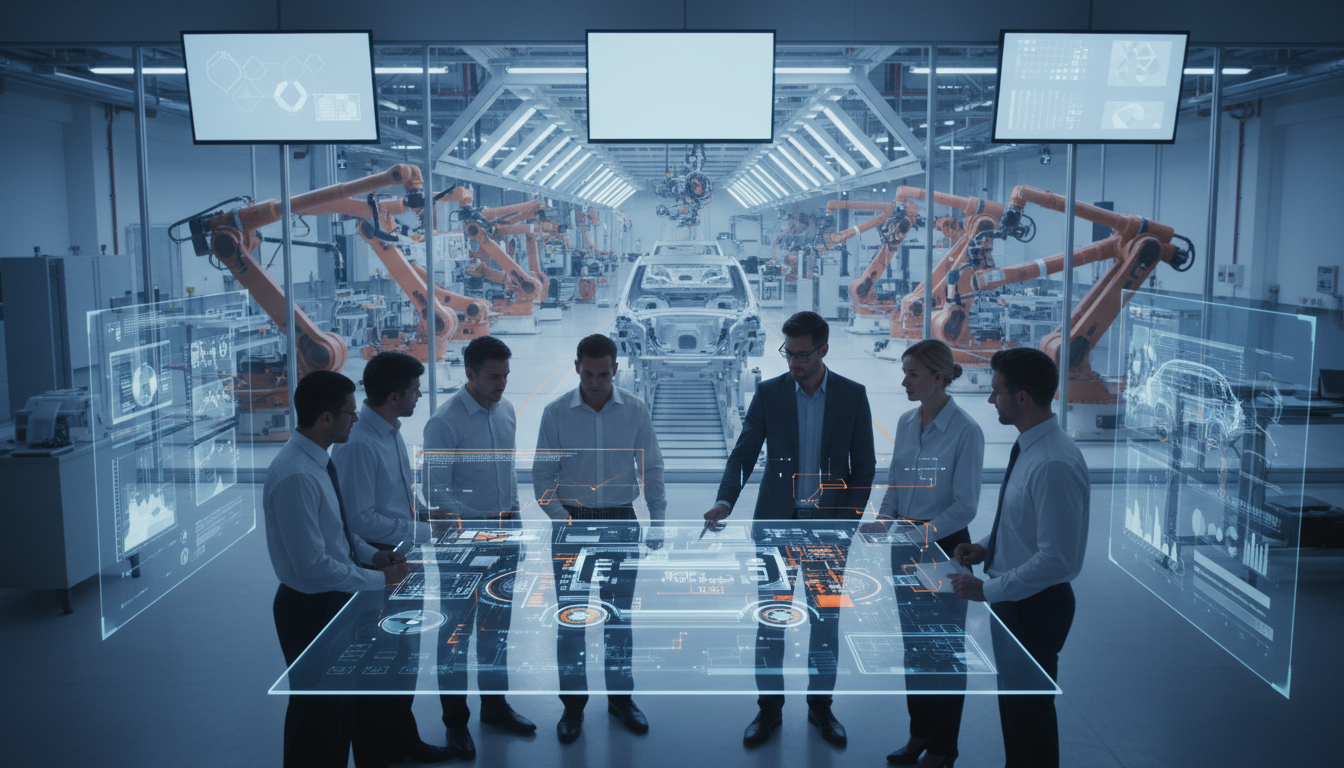

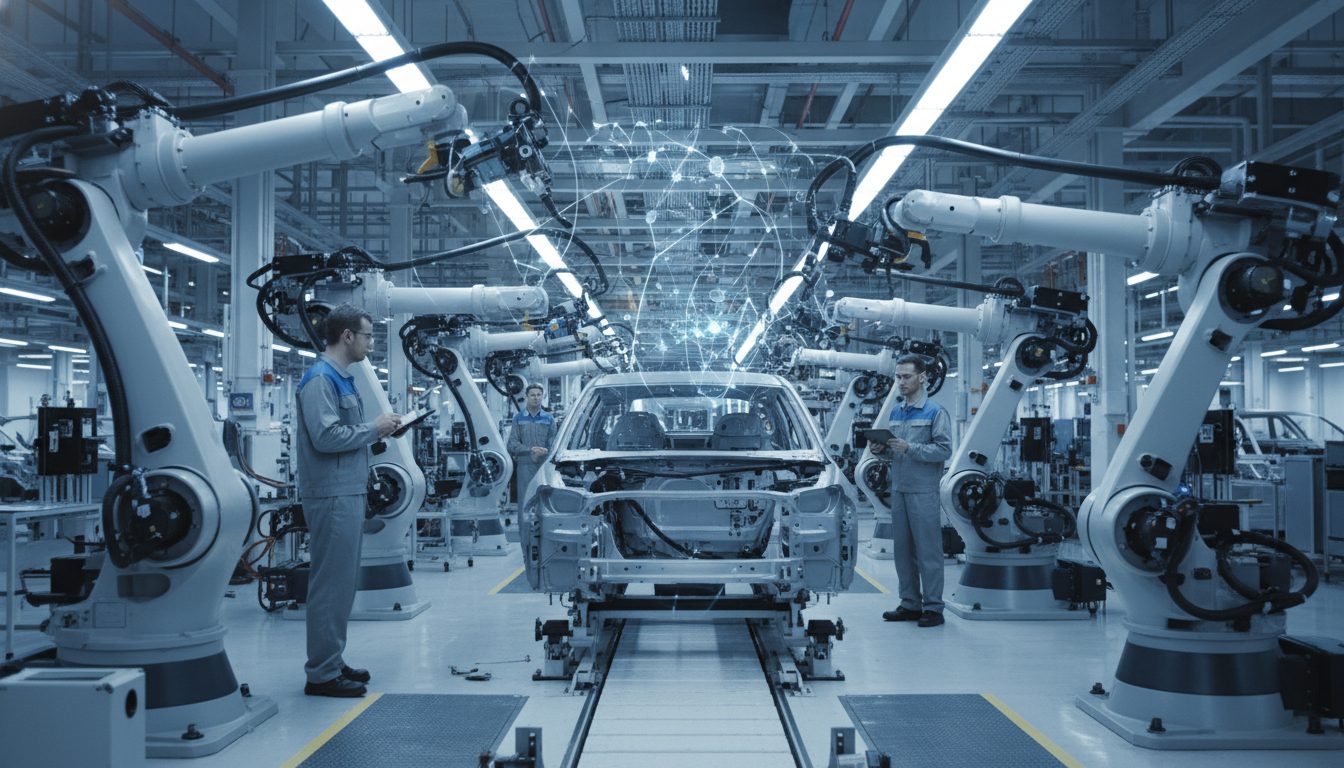

AI In Simulation Of Manufacturing Lines represents a transformative approach in the Automotive sector, where artificial intelligence is utilized to model and optimize manufacturing processes. This concept encompasses the integration of advanced algorithms and machine learning techniques to create dynamic simulations that reflect real-world manufacturing scenarios. As stakeholders navigate the complexities of modern production, the relevance of this approach becomes increasingly apparent, aligning with broader trends of digital transformation and operational excellence in the industry.

The significance of AI-driven simulation within the Automotive ecosystem cannot be overstated, as it reshapes competitive dynamics and accelerates innovation cycles. By leveraging AI, manufacturers can enhance efficiency, improve decision-making, and streamline stakeholder interactions, creating a more agile and responsive operational framework. However, the journey towards full adoption is not without its challenges, including integration complexities and evolving expectations that demand continuous adaptation. As organizations embrace these technologies, they open doors to vast growth opportunities while also confronting the need to overcome practical barriers to implementation.

Accelerate AI Adoption in Manufacturing Simulations

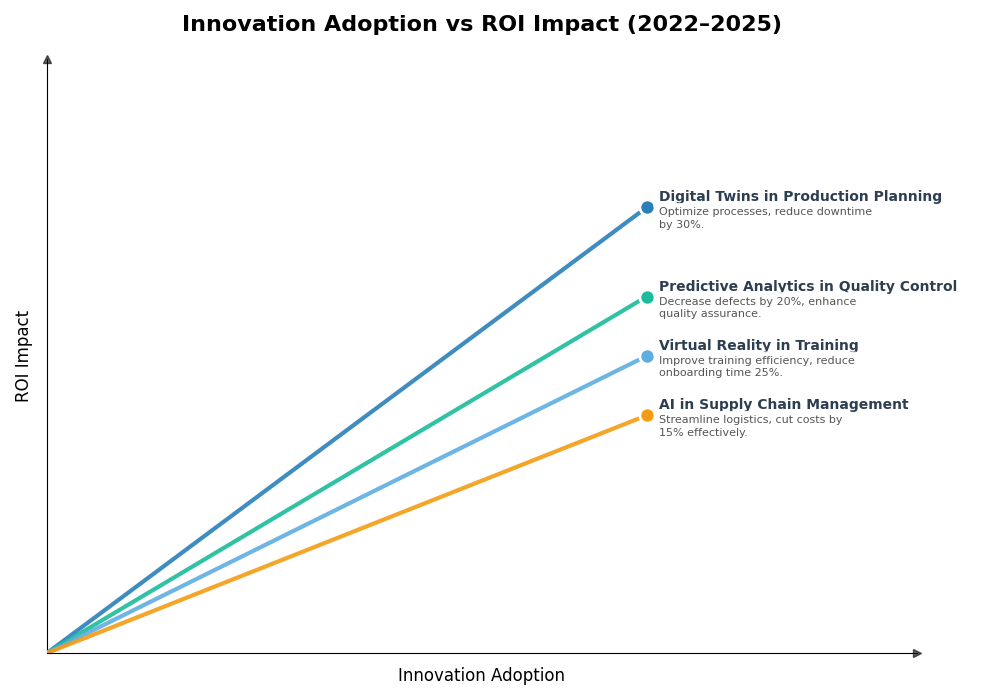

Automotive leaders should strategically invest in AI-driven simulations and forge partnerships with AI technology firms to enhance manufacturing line efficiencies. Implementing these AI solutions is expected to yield significant ROI through reduced operational costs and improved production accuracy, offering a competitive edge in the market.

Transforming Automotive Production: The Role of AI in Manufacturing Simulations

The Disruption Spectrum

Five Domains of AI Disruption in Automotive

Automate Production Flows

Enhance Generative Design

Simulate Real-World Testing

Optimize Supply Chains

Promote Sustainability Initiatives

Compliance Case Studies

| Opportunities | Threats |

|---|---|

| Enhance market differentiation through AI-driven manufacturing simulations. | Risk of workforce displacement due to increased AI automation. |

| Increase supply chain resilience with predictive AI analytics and simulations. | Over-reliance on AI may create technology dependency issues. |

| Achieve significant automation breakthroughs by optimizing production processes with AI. | Potential compliance hurdles with evolving AI regulations and standards. |

Seize the opportunity to enhance efficiency and reduce costs in your automotive production. Transform your operations today with cutting-edge AI simulation solutions.

Risk Senarios & Mitigation

Failing Compliance with Regulations

Legal penalties arise; ensure regular audits.

Compromising Data Security Measures

Data breaches occur; implement robust security protocols.

Inherent Algorithmic Bias Issues

Unfair outcomes result; conduct thorough bias assessments.

Operational Failures in Simulations

Production delays happen; establish contingency plans.

Assess how well your AI initiatives align with your business goals

Glossary

Work with Atomic Loops to architect your AI implementation roadmap — from PoC to enterprise scale.

Contact NowFrequently Asked Questions

- AI in Simulation of Manufacturing Lines enhances production efficiency through automated processes.

- It enables real-time data analysis, allowing for swift decision-making and adjustments.

- This technology helps reduce downtime by predicting and mitigating potential failures.

- Companies can optimize workflows, leading to significant cost savings and improved quality.

- Overall, it provides a competitive edge in the rapidly evolving automotive landscape.

- Begin with a clear assessment of your existing systems and processes to identify gaps.

- Engage stakeholders to define objectives and expected outcomes from AI implementation.

- Develop a phased approach, starting with pilot projects to test feasibility and impact.

- Invest in the right technology and partner with AI vendors for specialized expertise.

- Regularly review and adapt strategies based on pilot results and feedback from teams.

- AI can significantly reduce operational costs through optimized resource management.

- It enhances production quality by identifying defects earlier in the process.

- Companies often experience increased throughput due to improved process efficiency.

- Customer satisfaction improves as a result of faster and more reliable deliveries.

- Overall, AI provides a substantial ROI through enhanced productivity and reduced waste.

- Resistance to change is common; effective communication can help alleviate concerns.

- Data quality issues can hinder AI effectiveness; invest in data management solutions.

- Integration with legacy systems often poses technical challenges requiring expert guidance.

- Training staff to adapt to new technologies is crucial for successful implementation.

- Establishing clear goals and metrics can help navigate potential obstacles during rollout.

- AI can optimize assembly line processes, enhancing speed and accuracy of production.

- Predictive maintenance applications minimize downtime by foreseeing equipment failures.

- Quality control systems use AI to detect defects in real-time during production.

- Supply chain management benefits from AI through improved forecasting and logistics.

- These applications collectively enhance the overall efficiency of automotive manufacturing operations.

- Assess your current operational challenges to identify readiness for AI adoption.

- Consider market trends; companies adopting AI early often gain competitive advantages.

- Evaluate technological infrastructure; readiness facilitates smoother integration of AI solutions.

- Look for opportunities during periods of downtime for pilot testing AI initiatives.

- Regularly review industry benchmarks to determine optimal timing for your organization.

- Establish clear KPIs aligned with business objectives to track AI performance.

- Regularly review operational metrics such as throughput, quality, and cost savings.

- Engage team members for qualitative feedback on process improvements and user experience.

- Benchmark against competitors to gauge relative performance improvements post-implementation.

- Conduct periodic assessments to adapt strategies and enhance AI effectiveness over time.

- Conduct thorough risk assessments before initiating AI projects to identify potential pitfalls.

- Implement a phased rollout to manage risks effectively and learn from initial feedback.

- Engage cross-functional teams to ensure diverse perspectives on risk factors are considered.

- Invest in training programs to equip staff with necessary skills for AI technologies.

- Establish a monitoring system to quickly address issues as they arise during implementation.