AI In Next Generation Robotics

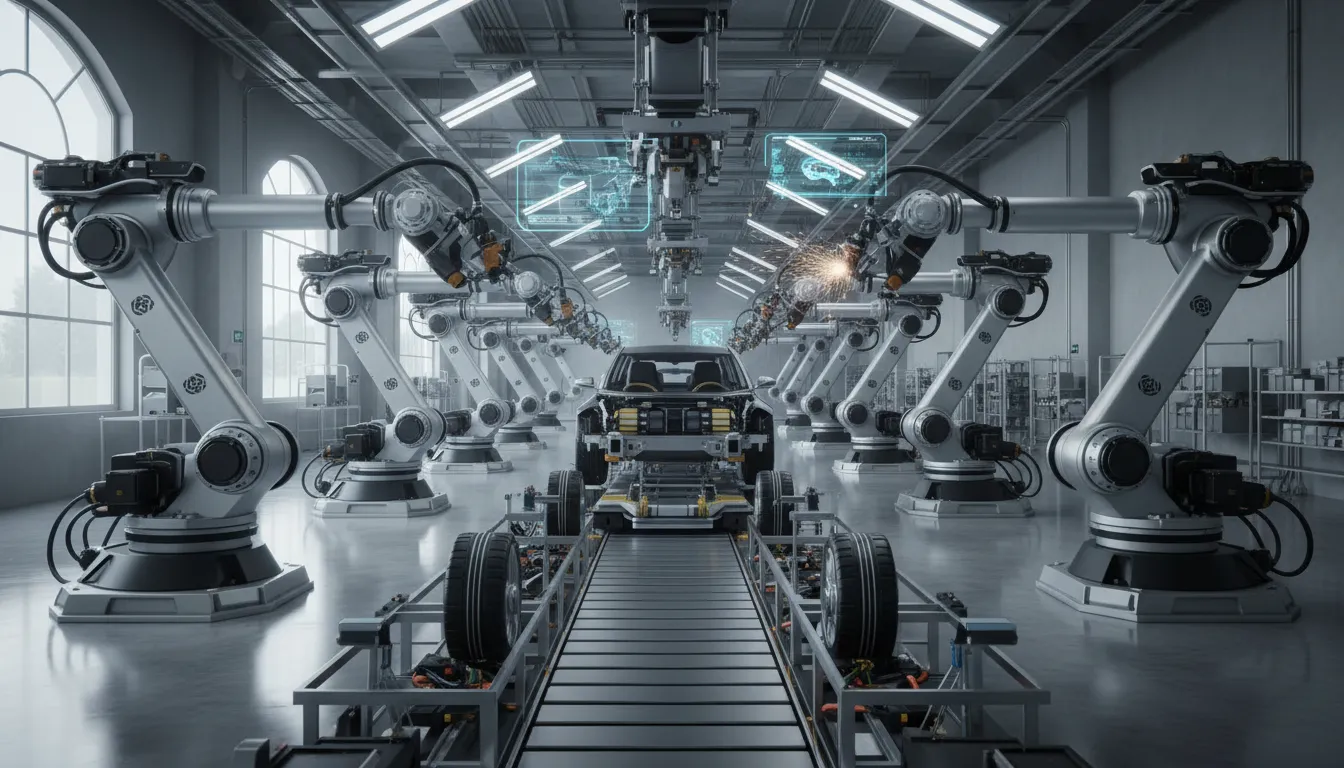

In the context of the Automotive sector, "AI In Next Generation Robotics" refers to the integration of advanced artificial intelligence technologies into robotic systems that enhance manufacturing processes, vehicle design, and operational efficiencies. This concept encompasses a wide range of applications, including autonomous vehicles, smart production lines, and intelligent supply chain management. As the industry navigates technological advancements, this integration is crucial for stakeholders aiming to maintain competitiveness and align with the shifting paradigms driven by AI-led transformations.

The Automotive ecosystem is witnessing a significant shift as AI-driven practices redefine competitive dynamics and innovation cycles. These advancements enable companies to enhance efficiency, improve decision-making processes, and foster more effective stakeholder interactions. As organizations increasingly adopt AI technologies, they encounter both growth opportunities and realistic challenges, such as integration complexities and evolving expectations. Balancing these aspects is vital for long-term strategic direction, ensuring that stakeholders can leverage the full potential of AI in robotics while addressing the hurdles that may arise in this transition.

Accelerate Your AI Robotics Strategies Now

Automotive companies should prioritize strategic investments and forge partnerships centered around AI in next-generation robotics to enhance their manufacturing and operational capabilities. Implementing AI-driven solutions can lead to significant improvements in efficiency, cost reduction, and a competitive edge in the rapidly evolving automotive market.

How is AI Revolutionizing Next-Gen Robotics in Automotive?

The Disruption Spectrum

Five Domains of AI Disruption in Automotive

Automate Production Workflows

Enhance Generative Design

Advance Simulation Techniques

Optimize Supply Chain Strategies

Promote Sustainability Initiatives

Compliance Case Studies

| Opportunities | Threats |

|---|---|

| Enhance market differentiation through smart automation solutions in vehicles. | Workforce displacement risks due to increased AI automation in factories. |

| Strengthen supply chain resilience with AI-driven predictive analytics tools. | Over-reliance on AI may lead to critical system vulnerabilities. |

| Achieve automation breakthroughs by integrating AI for real-time decision making. | Regulatory compliance challenges could slow down AI adoption processes. |

Embrace AI in Next Generation Robotics to elevate performance and outpace competitors. Transform your operations and unlock unparalleled efficiencies today.

Risk Senarios & Mitigation

Ignoring Compliance Regulations

Legal penalties arise; ensure regular compliance reviews.

Neglecting Data Security Measures

Data breaches threaten trust; invest in robust cybersecurity.

Overlooking AI Bias Issues

Unfair outcomes occur; implement diverse training datasets.

Experiencing Operational Failures

Production delays happen; establish rigorous testing protocols.

Assess how well your AI initiatives align with your business goals

Glossary

Work with Atomic Loops to architect your AI implementation roadmap — from PoC to enterprise scale.

Contact NowFrequently Asked Questions

- AI in Next Generation Robotics enhances manufacturing processes through automation and precision.

- It streamlines supply chain operations by predicting demand and optimizing logistics.

- Robotics equipped with AI improves quality control with real-time monitoring and analysis.

- This technology enables faster product development cycles and reduces time-to-market.

- AI-driven robotics also enhance safety by minimizing human error in hazardous environments.

- Begin by assessing your current processes and identifying areas for automation.

- Establish a clear strategy that aligns AI objectives with business goals and resources.

- Invest in employee training to ensure a smooth transition to AI-powered systems.

- Pilot projects can demonstrate value before full-scale implementation to stakeholders.

- Engage with technology partners who specialize in AI and robotics solutions.

- Companies often experience increased operational efficiency leading to higher output.

- Cost savings are realized through reduced manual labor and improved resource utilization.

- Customer satisfaction improves due to consistent quality and faster delivery times.

- Data-driven insights enhance decision-making and strategic planning processes.

- Competitive advantages emerge as businesses innovate faster and respond to market changes.

- Resistance to change from employees can hinder the adoption of new technologies.

- Integration with legacy systems poses technical hurdles that require careful planning.

- Data privacy and security concerns must be addressed to protect sensitive information.

- Skill gaps in the workforce need to be bridged through targeted training programs.

- Managing expectations around AI capabilities is crucial to avoid overpromising results.

- Stay informed about local and international regulations impacting AI technologies.

- Implement data governance practices to ensure compliance with privacy laws.

- Regular audits can help assess adherence to regulatory standards and guidelines.

- Collaborate with legal teams to navigate complex regulatory landscapes effectively.

- Emphasize transparency in AI operations to build trust with stakeholders and customers.

- Evaluate your competitive landscape to identify pressure points for innovation.

- Consider adopting AI when facing inefficiencies that impact productivity and costs.

- The readiness of your infrastructure will dictate the timing for implementation.

- Market trends towards automation can signal a ripe opportunity for investment.

- Engage stakeholders to ensure organizational alignment and readiness for change.