AI Adoption in Quality Control Automotive

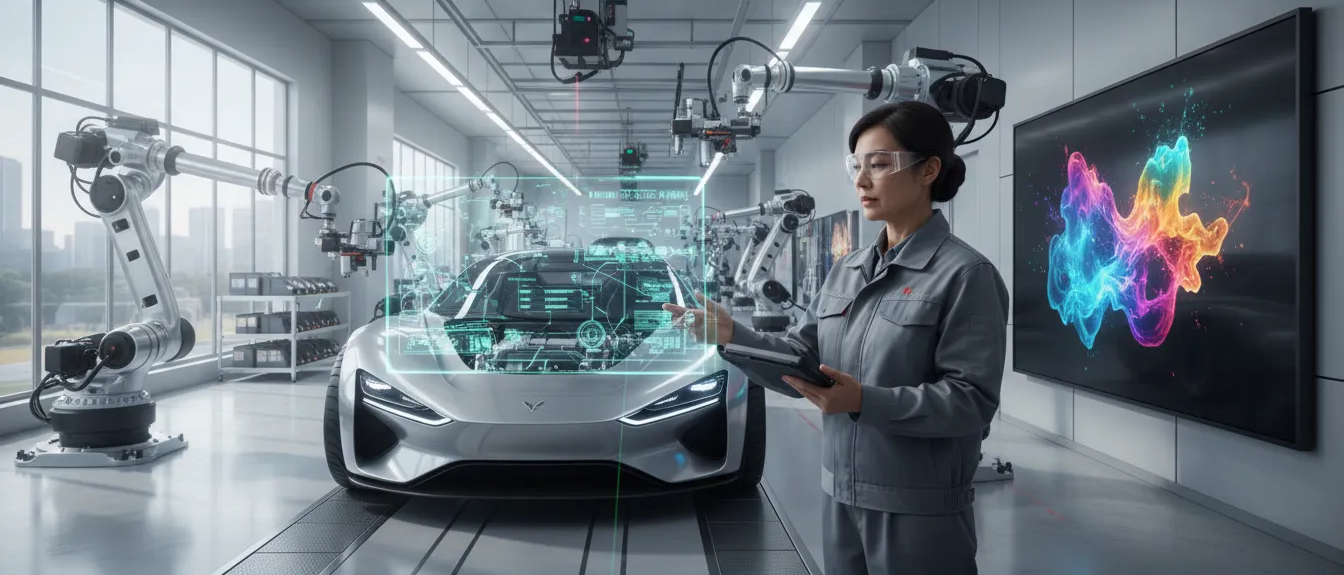

AI Adoption in Quality Control Automotive refers to the integration of artificial intelligence technologies to enhance quality assurance processes within the automotive sector. This transformation enables manufacturers to leverage data-driven insights, automate inspections, and improve defect detection, aligning with broader trends of digitalization and operational efficiency. As stakeholders face increasing pressure to innovate and meet stringent quality standards, the relevance of AI adoption becomes paramount in driving operational excellence and strategic advancements.

The Automotive ecosystem is undergoing a paradigm shift driven by AI adoption in quality control processes. Advanced analytics and machine learning are redefining competitive dynamics, facilitating faster innovation cycles, and enhancing stakeholder collaboration. By improving efficiency and decision-making capabilities, AI is poised to reshape strategic directions for manufacturers. However, the journey is not without challenges; barriers to adoption, complexities in technology integration, and evolving expectations from consumers and regulators present significant hurdles. Navigating these realities will be crucial for organizations looking to harness the full potential of AI-driven quality enhancements.

Accelerate AI Adoption for Superior Quality Control in Automotive

Automotive companies should strategically invest in AI technologies and forge partnerships with leading tech firms to enhance their quality control processes. By implementing AI-driven solutions, businesses can expect improved defect detection, reduced costs, and significant competitive advantages in the market.

Revolutionizing Quality Control: The Role of AI in Automotive

Implementation Framework

Conduct a thorough evaluation of existing quality control processes to identify inefficiencies. This analysis informs AI integration, ensuring alignment with operational goals while enhancing product quality and reducing waste in automotive manufacturing.

Industry Standards}

Deploy AI solutions tailored for quality control, such as machine learning algorithms for defect detection. This integration enhances accuracy, speeds up inspections, and decreases costs while maintaining high quality standards in automotive production.

Technology Partners}

Provide comprehensive training for employees on new AI technologies and tools. This ensures that the workforce is equipped to utilize AI effectively, fostering a culture of innovation and continuous improvement within the quality control framework.

Internal R&D}

Establish key performance indicators (KPIs) to monitor the effectiveness of AI in quality control. Regular evaluation helps refine processes, ensuring that AI contributes positively to quality outcomes and operational efficiency in automotive manufacturing.

Industry Standards}

Continuously iterate and refine AI-driven quality control processes based on feedback and data analysis. This ensures that the AI system evolves with changing demands, enhancing resilience and responsiveness in automotive supply chains and quality objectives.

Cloud Platform}

AI is revolutionizing quality control in automotive manufacturing, enabling unprecedented precision and efficiency in production processes.

– Jim Vinoski

AI Use Case vs ROI Timeline

| AI Use Case | Description | Typical ROI Timeline | Expected ROI Impact |

|---|---|---|---|

| Predictive Maintenance Analytics | AI algorithms analyze machine data to predict failures before they occur. For example, a car manufacturing plant uses AI to monitor equipment health, reducing downtime and repair costs. This proactive approach enhances operational efficiency and extends equipment life. | 6-12 months | Medium-High |

| Automated Visual Inspection | AI-driven image recognition identifies defects in components during assembly. For example, an automotive supplier employs AI cameras to inspect parts, ensuring only high-quality components pass through, leading to fewer recalls and improved customer satisfaction. | 6-12 months | High |

| Quality Control Data Analytics | AI tools analyze historical quality data to identify trends and anomalies. For example, an automotive manufacturer uses AI to analyze production line data, uncovering root causes of defects and enabling continuous improvement efforts. | 12-18 months | Medium-High |

| Supply Chain Quality Monitoring | AI systems monitor the quality of materials supplied to manufacturers. For example, an automotive company employs AI to evaluate supplier performance in real-time, ensuring materials meet quality standards and reducing waste. | 12-18 months | Medium-High |

AI is revolutionizing quality control in the automotive industry, enabling unprecedented precision and efficiency in defect detection and process optimization.

– Rex Lam, Industry Leader at CapgeminiCompliance Case Studies

Embrace AI-driven solutions to enhance quality control in your automotive processes. Stay ahead of the competition and unlock new efficiencies and insights now.

Assess how well your AI initiatives align with your business goals

Challenges & Solutions

Data Integrity Challenges

Implement AI-driven data validation tools in Quality Control to enhance data accuracy and consistency across all automotive processes. By employing machine learning algorithms, manufacturers can identify anomalies in real-time, ensuring that only high-quality data informs decision-making, thus enhancing overall product reliability.

Change Management Resistance

To address resistance to AI Adoption in Quality Control, foster an inclusive culture by engaging employees in the transition process. Utilize AI-driven communication platforms to provide transparent updates and training, which can alleviate fears, promote acceptance, and demonstrate the tangible benefits of AI integration in enhancing quality assurance.

Initial Implementation Costs

Mitigate high initial costs of AI Adoption in Quality Control by adopting a phased implementation strategy. Start with pilot projects focusing on critical quality issues, allowing for measurable ROI to justify further investments. This approach reduces financial risk while demonstrating value, paving the way for broader implementation.

Regulatory Compliance Risks

Utilize AI technologies in Quality Control to automate compliance monitoring and reporting. AI can analyze vast amounts of data to ensure adherence to industry regulations, providing real-time alerts for non-compliance. This proactive approach not only minimizes legal risks but also enhances operational transparency.

AI is revolutionizing quality control in the automotive industry, enabling unprecedented precision and efficiency in manufacturing processes.

– Jim VinoskiGlossary

Work with Atomic Loops to architect your AI implementation roadmap — from PoC to enterprise scale.

Contact NowFrequently Asked Questions

- AI Adoption in Quality Control enhances accuracy through machine learning algorithms analyzing data.

- It reduces human error and increases efficiency in quality assurance processes.

- Companies can achieve higher product consistency and customer satisfaction levels.

- Real-time monitoring allows for immediate adjustments and proactive quality management.

- This technology positions firms competitively in a rapidly evolving automotive market.

- Begin with a clear strategy that outlines specific quality improvement goals.

- Assess existing systems to determine integration feasibility with AI technologies.

- Engage stakeholders to gather support and foster a collaborative implementation culture.

- Invest in training for staff to ensure they can effectively utilize AI tools.

- Pilot programs can help in refining processes before full-scale implementation.

- AI-driven quality control leads to reduced defect rates and operational costs.

- Companies often experience increased production speed and resource efficiency.

- Data analytics provide actionable insights that drive continuous improvement efforts.

- Customer satisfaction scores typically rise due to enhanced product quality.

- Competitive advantages are gained through innovation and quicker response to market changes.

- Data quality and availability can hinder effective AI implementation efforts.

- Resistance to change among employees may slow down adoption processes.

- Integration with legacy systems often poses significant technical challenges.

- Organizations must navigate regulatory compliance to ensure AI usage is lawful.

- Addressing these challenges requires clear communication and strategic planning.

- Organizations should consider AI adoption when facing persistent quality issues.

- Early adoption can be beneficial during product development phases for better outcomes.

- Market competition pressures can signal the need for technological advancements.

- Timing also depends on readiness in terms of infrastructure and workforce skills.

- Regular assessments of industry trends can guide strategic timing for adoption.

- Establish clear objectives that align AI initiatives with business goals.

- Involve cross-functional teams to ensure diverse perspectives and expertise.

- Regularly evaluate AI systems to identify areas for improvement and adaptation.

- Foster a culture of continuous learning and innovation within the organization.

- Effective communication is essential to manage expectations and promote buy-in.

- Compliance with industry standards is crucial for maintaining quality assurances.

- AI systems must meet regulatory requirements to avoid legal pitfalls.

- Regular audits help ensure AI practices align with compliance frameworks.

- Transparency in AI decision-making enhances trust among stakeholders.

- Staying informed about evolving regulations is vital for ongoing compliance.

- AI can be employed in predictive maintenance to anticipate quality issues.

- Automated visual inspections can detect defects more efficiently than humans.

- Supply chain optimization through AI enhances material quality and availability.

- AI-driven analytics inform design improvements to minimize production errors.

- Real-time quality monitoring systems empower proactive issue resolution.